Personal Protective Equipment (PPE) is Standard Operating Procedure for construction personnel. For most resident engineering staff members, the staples of our PPE are:

–Hardhat

–Safety Glasses

–Hearing Protection

–Work Boots

–Work Gloves

–Hi-Vis Safety Vest

A colleague recently told me that the Illinois State Toll Highway Authority (one of our company’s clients) may be in the process of changing their safety vest requirements, requiring that all on-site workers wear Class 3 rated vests (in lieu or the previously required Class 2 vests).

It got me thinking: Do engineers know the significance of safety apparel classes?

Do you know the difference? What differentiates Class 1, 2 vs. 3?

Let’s take a look

Who is ANSI?

ANSI is the American National Standards Institute – They are a private organization that establishes standards for thousands of classes of products and services. In the US, the Occupational Safety and Health Administration (OSHA) oversees and enforces worker conditions. OSHA uses ANSI standards for several PPE categories, including:

–Eye & Face Protection

–Head Protection

–Foot Protection

For safety vests & safety apparel, ANSI has developed rating classifications for high visibility apparel which is based on several different criteria:

–Work environment risk exposure

–Total reflectivity of the apparel

–Total area of color contrast of the apparel

Let’s look at the 3 rating classifications most-known to the construction industry.

ANSI Class 1 Safety Vest

A Class 1-rated vest carries the lowest rating of all of the safety apparel classifications because it has the lowest amount of reflective material. In the road & bridge construction industry, this class is typically not used. The vest can be green or orange and has a minimum of 155 square inches of reflective tape on it with the tape wrapping the mid-section and the shoulders. These vests are typically used in non-traffic exposed areas, like auditoriums, sporting events or parking lot operations where the color contrast is important but reflectivity, or traffic exposure conditions are considered low speed.

ANSI Class 2 Safety Vest

A Class 2-rated vest has been the standard specified vest type for numerous governmental transportation agencies. These vests are typically required where the worker is exposed to traffic speeds of 50mph or less. A Class 2 vest must have at least 201 square inches of reflective tape on it as well as at least 775 square inches of contrasting yellow or green background material.

This is the most-commonly used class of vest in road & bridge construction. Some agencies will have specific requirements insofar as major background color and reflective stripe configuration (some railroads, for example, require orange vests with a cross-buck reflective stripe).

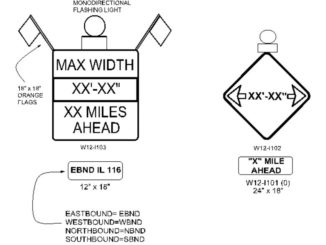

ANSI Class 3 Safety Vest/Apparel

The Class 3 rating requires the highest area of contrasting color exposure – 1240 square inches or more of contrasting yellow or green background material and at least 310 square inches of reflective material. Because of the need for such a high contrasting area, these usually are more likely to be a sleeved shirt-type vest. Many agencies require flaggers working in night-time work activities to be fully-covered in Class 3 apparel, meaning both shirts AND pants of contrasting color & reflectivity are necessary.

ACTION ITEMS:

I’ll give you a small assignment today of questions to get answered:

Talk to your company safety rep on your current SOP’s for traffic safety apparel. Find out if any of the agencies that you are working for are upgrading their ANSI classification requirements this year. What ANSI class of vest do you currently own? And is it appropriate for your client and exposure level?

Check your gear:

–Is your vest worn out? Is it dirty or ripped? Does it need to be washed? Or should it be replaced?

Check the washing instructions on your vest – Most have a maximum numbers of wash cycles you can use before the reflective material becomes unsatisfactory. If you haven’t cleaned it in a while, don’t wait for you mom to empty your hamper for you, take action and clean it.

–Is the reflective tape still functional?

–Have you been wearing a Class 1 vest and need a different class for your exposure level?

–Does your client have a safety clothing/PPE requirement that you & your crew should be following?

Take a couple of minutes this morning to check your gear: Let’s be honest: You don’t have to be a certified safety representative to look at your vest and know whether it ought to be replaced or not: You have enough common sense and where-withall to answer the question for yourself….Be proactive and get it replaced if you need a new vest.

SIDE NOTE:

A lot of guys I work with “like the look” of an old, broken-in, tattered safety vest. Some guys think that equipment that looks “Lived In” makes you look “Experienced,” or “Not-the-Newbie-on-the-Site.” I hate to admit it: Nobody like breaking-in new equipment, least of all a stiff newly-minted safety vest. I really do miss some of my old vests. They are broken in, I know where all my vest pockets are. Vests (like hardhats) are kind of like old friends that you hate to part with after you’ve logged tough miles in them…..

Reality Check: Drivers aren’t paying attention to whether or not your gear looks “Lived In.” Our work zones are hazardous. All day, we see drivers in our work zones, phones in-hand texting away. How many more rear-end accidents have you noticed in the past few years inside your workzone – INSIDE YOUR OFFICE??!! BE SEEN!!

Wash-up or change out your vest. Your employer will have ABSOLUTELY NO PROBLEM buying you & the people on your crew new vests. Go ahead and be the guy who looks like it’s his first day on the job – Your vest gets you noticed AS ITS SUPPOSED TO!! Be the example for you and your crew. Go home safe tonight.

Bob,

I am a Certified Safety Professional and ventured upon your site while looking for toolbox talk topics. I sometimes have to put together my own toolbox talks as well as JSA’s for safety on various construction projects. I have about 15 years of safety experience and many more in construction and environmental engineering. If you want to send me an email, I might be able to help you out on the safety aspects of your web site.