As you may/may not know from spending time at this site, I am a volunteer with the Plainfield Emergency Management Agency. It’s an organization that made up of about 20 volunteers who support our local police, fire & public works departments in Plainfield, Illinois.

Wednesday nights are typically training nights for the PEMA crew. Members of the command staff train front-line responders on all sorts of topics relevant to our work . For me, still being a rookie with the group, the topics are always educational and interesting – I need the ramp-up given my limited knowledge base. Some topics are specifically emergency response-related, while some double-over and have a direct correlation to my day-to-day activities as a construction engineer. Regardless of the topic or scenarios, I always learn something: Tools in the toolbox.

We train in the classroom. We train in the field. We train hands-on. We practice. And even though it’s only 1 night a week, it’s not a lot of training, but it’s frequent, regular, adds skills, reinforces and reminds.

I Love to Train

I think the beauty of para-military groups like PEMA, and why I’m so attracted to them, is because of the discipline they require – There is a cadence, a hierarchy, a command structure. Being regimented, functional, methodical, deliberate in the training and the way that our activities are carried out is brings order.

And then I think about my daytime activities: Do civil engineers attack their operations with that same kind of training mindset as we do at PEMA? Answer: No.

Do we role play? No.

Do we run through practice scenarios? No.

Do we do After Action Reviews or Hot Washes after we troubleshoot an issue?

When is the last time we did a Hands-On skill refresher?

Why Don’t Engineers Train More?

What is it about the civil engineering industry that doesn’t promote, say, toolbox talks? Or weekly safety training sessions? Or reviewing & training on small break-out topics that might be useful to the crew?

Most engineering companies promote “Lunch And Learns,” where a manufacture’s rep might stop in, buy Panera box lunches for everyone, the discuss/pitch/promote their product or software. But typically, these are design office-type sessions. Let’s face it: As construction engineers, we have concrete pours, subgrade shots and drilled shaft monitoring to do all throughout the day – Contractors don’t shut down operations so that we can go to a seminar.

We all get mailers and e-vites from training companies selling webinars and 2- and 3-day seminars on the 400-Level Class type subjects, like HEC-RAS programming, high performance concrete or other technical-based subjects that are of little interest to construction engineers.

Of course, if you’re a PE like me, we have the 30 CEU requirement for license renewal, which of course promotes us to stay current. But ask yourself this:

What percentage of your CEU credits are directly applicable to your daytime duties as a construction engineer.

I’d bet it’s not 100%…

Maybe It’s Me….

You know – Maybe, in 30 years of construction engineering, the training culture on our side of the house hasn’t kept pace with that of the contracting industry. Maybe my experience/exposure has been outside the norm.

Or, digging even further – Maybe I’m the problem: I’m not promoting regular training sessions for myself and/or my crews on the projects I’ve run. I’m not leading like I ought.

Most likely, it’s a combination of all of the above.

Let me tell you a quick story to drive home my point.

Jacking Pit #4 Hazardous Waste

On one of my recent projects, our GC began work on constructing a 35′ deep storm sewer jacking pit. The Contractor drove sheeting for the pit and began excavation. His first 4 loads of excavated material were rejected due to high PID readings.

Upon further investigation by the environmental firms, it was determined that trichloroethylene was present in the soil requiring the excavated material to be treated as special waste. Since the GC did not have the proper credentials to handle this type of waste material, he would need to subcontract the work out to have the material properly removed & disposed.

R.W. Collins was secured by the GC to perform the work. After several months of paper prep work, their crew mobilized to the site.

The first morning of the op, Tom Cook, R.W. Collins’ project manager, called me over to his foreman’s truck, along with the operators, laborers & environmental monitoring engineer who would all be working on the site. Tom gave the morning Project Safety Brief: He walked the crew through the various procedures & protocols that they would need to be aware of to execute the job: Truck movements, traffic flagging, environmental monitoring, PPE, etc. Tom hit the job from all sides: Ladder use, confined space & air supply, slips & trips, traffic conditions and how that would effect getting trucks in-and-out of the site, weather, wind conditions. Tom gave an outstanding brief.

When Tom was finished, I pulled him aside and thanked him for letting me participate in the brief. I explained to Tom about my work with the Plainfield EMA and how our operations are similarly conducted with protocols, procedures, briefs prior to the op. I told Tom how I wished my industry, the technical & engineering side of the house, would run similar briefs for our activities like Tom did for us this morning.

So, as I got back into my truck, I made a pact with myself: I need to be better. I need to start promoting day-to-day work briefs. As a leader, it can, should & must start with me.

I had no idea, while sitting in my truck, what the forum would be or how I would carry out my mission, but I knew I wanted & needed to start to be more deliberate with my crew. I wanted to figure out how I could do something proactively so that, my guys, my teams, hell, our entire industry – WE can all up our games.

What you are now reading, and will be seeing more of on this site, will follow lock-step, in similar fashion, to what I experienced with RW Collins: A morning brief.

A technical refresher.

A short, easily-digestible and totally-usable topic of interest to apply during the workday.

The topics will likely be things that you already know. AND THAT’S THE BEAUTY OF IT!!

We ALL need to be reminded of things we already know.

It doesn’t matter if you are a seasoned industry veteran or a budding, young college graduate – ALL OF US need to be training more often. Why?

Training reinforces discipline.

Training promotes good habits.

Training builds repetition.

Training makes us better engineers.

Training never ends – It is a lifelong pursuit.

Look, the construction industry is too large & too dynamic of a field of knowledge for any of us to ever consider ourselves to ever become “Masters” or “Experts.” We always need to be training. Learning. Reviewing. Refreshing. Expanding our knowledge base.

THE PLAN

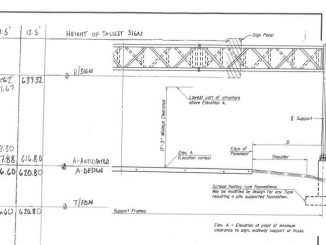

My plan is simple: Post a couple of TAILGATE TALK items per week. Short posts (not my usual essays…) pulling topics & information from all kinds of sources RELEVANT TO CONSTRUCTION ENGINEERS. Anything is fair game:

—Resident Engineer’s Toolbox Topics (my previous articles)

–Traffic Control & Site Safety Issues

–Site Operations

–Excel & Scheduling

–Construction Inspection & Documentation

–Technical Topic Refreshers

–Etc., Etc., (and there are LOTS of Etc.’s to explore….)

Repeat Comment from Above: Repetition Builds Habits.

I have a small platform here: Maybe I can make a dent.

ACTION PLAN

Here’s my suggestion: Check-into TAILGATE TALK every so often. Hopefully, I’ll stumble onto a topic or two that resonate with you, the construction engineer, who is looking to up his/her game.

The more tools you have in your toolbox, the bigger your arsenal gets: You become better at your craft so long as you practice your skills.

Remember: Tools need to be maintained:

Sharpen the tools that that need sharpening.

Knock the rust off the tools that are dirty.

Pull the tools out of the bottom of the box once in a while.

Practice your craft – EVERYDAY.

Let me know what you think.

1 Trackback / Pingback