Being a construction engineer is kind of like being an ER doctor or nurse – You never quite know what kind of challenge is going to walk in the door, but you have to be prepared for to respond it.

One of the primary challenges that construction engineering brings with it is the broad scope of knowledge that one must posses to be good at the craft. Think of the wide variety of installation elements that are involved with, say, building a street in a subdivision. Even though the finished product might simply just be an asphalt road built on stone with curb & gutter along side of it, there’s a drainage system under it. The soil conditions that the road is built can sometimes change every few hundred feet. Utility crossings. The road could be either asphalt or concrete, so the understanding of the material production, performance & installation techniques come into view.

There are areas of knowledge that we may need to only dip into once a job, or once a construction season. And if you’ve never had to apply a technique or inspect & administer the installation of an element that you haven’t dealt with in a while, you might question what you are doing. Or you might tackle a task using the wrong methodology. But if you didn’t know the right technique in the first place, how do you make the course correction?

How do we become proficient in such a variety of knowledge areas?

It’s called Lifelong Learning.

You are kidding yourself if you think you know everything. Everyday you have a chance of someone throwing something at you that you think you know. Or that you should know. But you don’t know.

And that’s OK. The key is knowing what to look for and where to look for solutions.

I’m going to help you with one of those solutions today that deals with a jobsite element that we, as construction engineers, often-time take for granted. Let’s take a look at seeding calculations. In this article, I want to take a look at seeding as it applies to heavy highway construction project restoration.

OK, I know you’re already thinking about hitting the “X” in the corner of the window, closing this article, and clicking over to your Instagram feed – I get it, this one sounds like a colossal waste of a read. But – I’m going to challenge you with a question that, if you can answer correctly, you can close this article and go watch YouTube videos:

What is the proper way to do a yield check on seeding pay items?

If you know the answer, I’ll say Goodbye. If you don’t know, or you think you know but you’re not sure, then keep reading.

Jobsite Seeding

Let’s establish a jumping-off point for ourselves so that we all start at the same place. It’s Fall. Our job is wrapping up. The Contractor is topping out areas, punching the job, and the landscapers have made it to the jobsite to put the final coat of paint on our project. Topsoil is spread and we’re ready for seed.

The landscaper gets to the jobsite with lots of different bags of seed. For discussion purposes, let’s assume that your job will be placing a variety of seed types:

–A regular roadside mix grass seed

–A specialty wetland-type seed

–A native grass-type seed, and

–A temporary erosion control seed

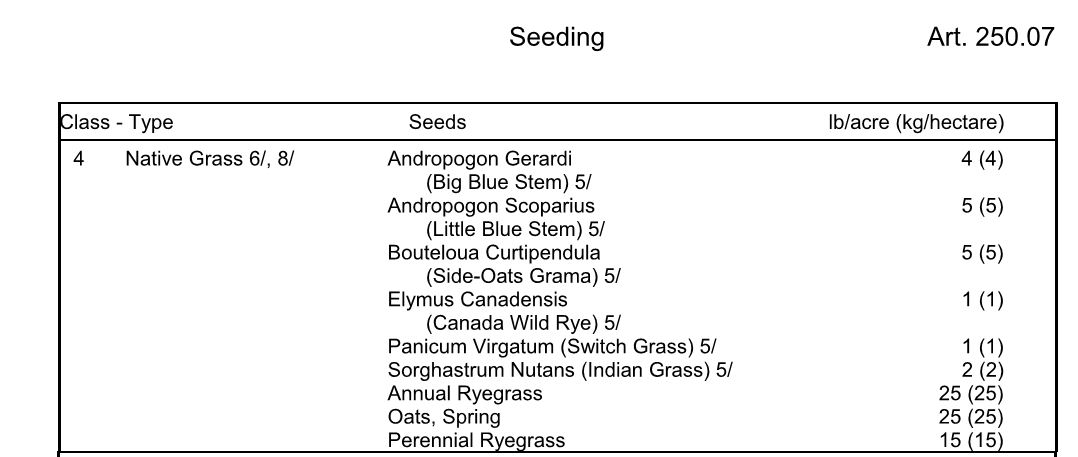

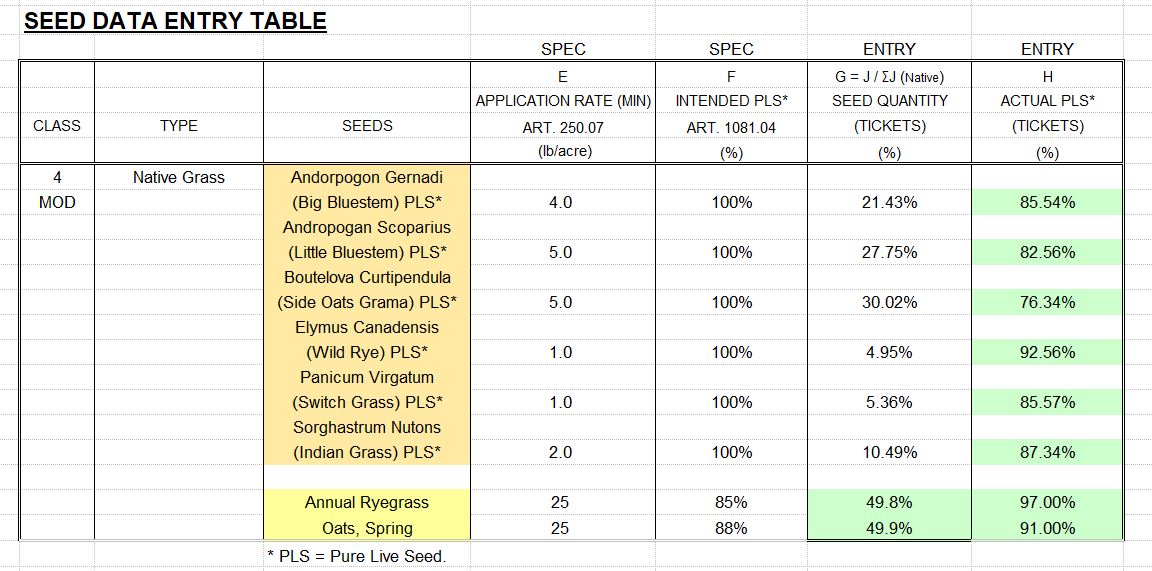

So one thing we know is that all of these seed types have different application rates. Our specifications will give us those rates. Let’s take a look at an example that we often use on expressway projects – IDOT Class 4 – Native Grass.

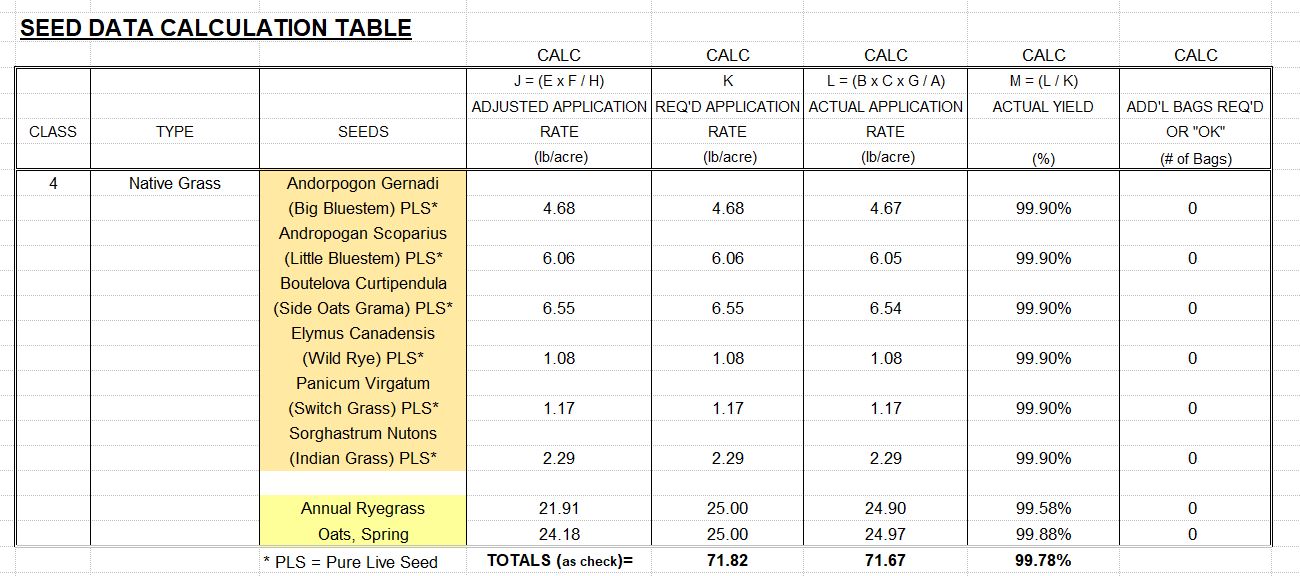

If we look at the seed blend, there are a couple of notables. The first 6 seed types are essentially specialty grasses in the seed blend that give the finished product variations in color or growing height. The last 3, the ryegrasses and oats are the base grasses in the mix.

If we look at the application rates, we can see some really big differentials – The native grasses are applied at only a few pounds per acre while the ryegrasses & oats are applied at a much heavier rate.

So, when our seed is shipped to the site, how is it blended? Does it come in one big bag that gets applied all at once? How does the landscaper control the rates?

This type of grass seed ships to the job in 2 separate bags: The native grass seeds will come in a pre-blended bag and the oats & ryegrass will come in another.

The seeds are typically sown in separate applications: Usually, the landscaper will use a grass drill so that he can control the application of the native grass installation. There have been times when a landscaper has requested to use a hand broadcast spreader in wetland-type areas where the equipment might not be able to navigate soft or isolated areas.

Some of the native, and particularly the wetland, sedge & forb seed mixes are very expensive so you want to make sure that they are applied accurately. Ryegrass & oats are much larger & heavier seeds that, because of their application rate, usually require a separate equipment setup & application (that’s just been my experience with the landscape contractor’s I’ve worked with…).

The native grasses all have variable application rates (pounds per acre). The seed supplier will produce the blend that is shipped. So here’s a quiz: If the mix is comprised of so many varieties of seed types and variable application rates, how do you know how much area your bag of seeds will cover?

Seeding Delivery Tickets & Certifications

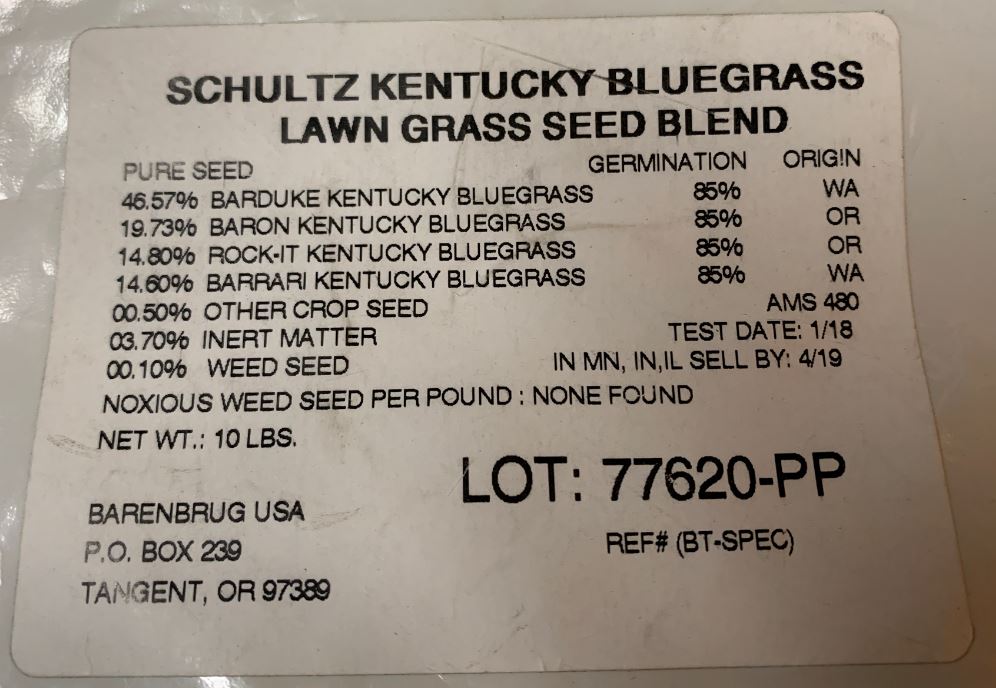

When the seed is shipped from the supplier, you’ll receive a seed tag with it.

If you learn anything from this post, learn this: DON’T THROW THE SEED TAGS OR BAGS AWAY – KEEP EVERYTHING!!!!

When you get your seed tag, you will see the seed type, blend, etc. On the ticket, the supplier will stamp how much area the bag of seed covers. Typically, the landscaping contractor will tell the supplier how much area he needs to cover and the supplier will customize a bag specifically covering that area. You need that information both for checking that the landscaper is going to apply the correct seed in the correct location but you also need it to later confirm that the quantities you are paying for match what you’ve received.

Now, since the landscaper is applying a “material” (in this case seed) and you have a measured area that you will be paying for (typically in acres), you need to do a yield check to make sure that the specified amount of seed was placed on the area you measured. How do you do that? I’ll bet you think you just take the weight of the bags and divide it by the area that you applied and that’s your check, right..??

WRONG.

Let’s talk about Pure Live Seed.

Pure Live Seed

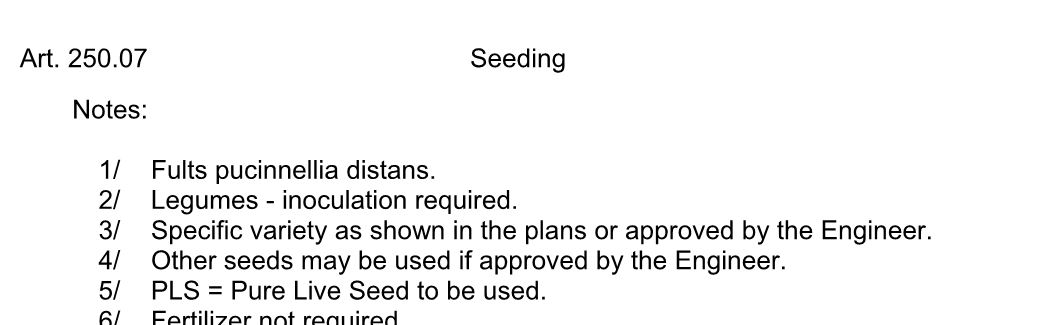

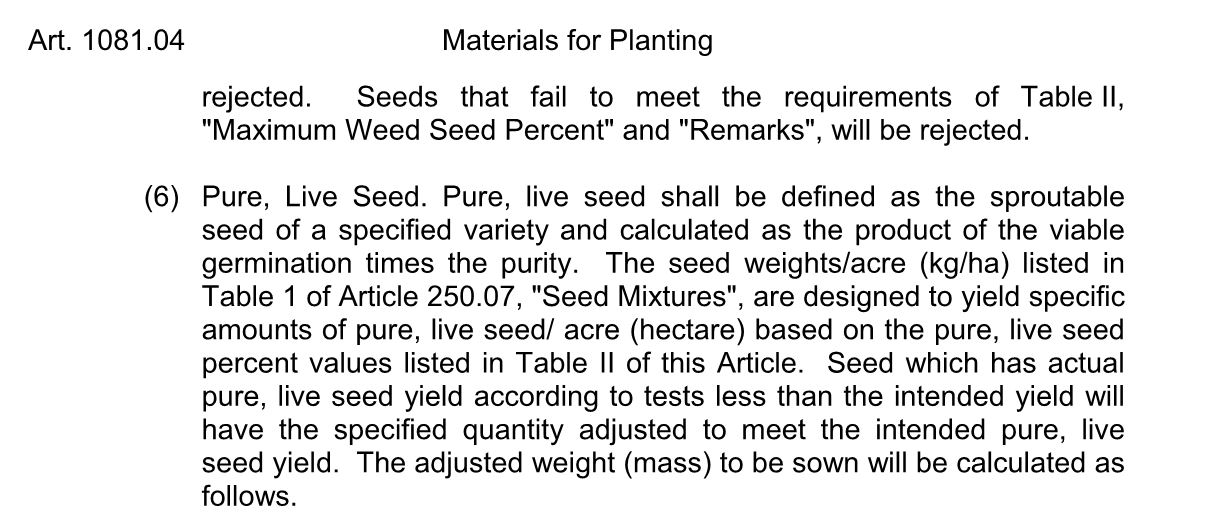

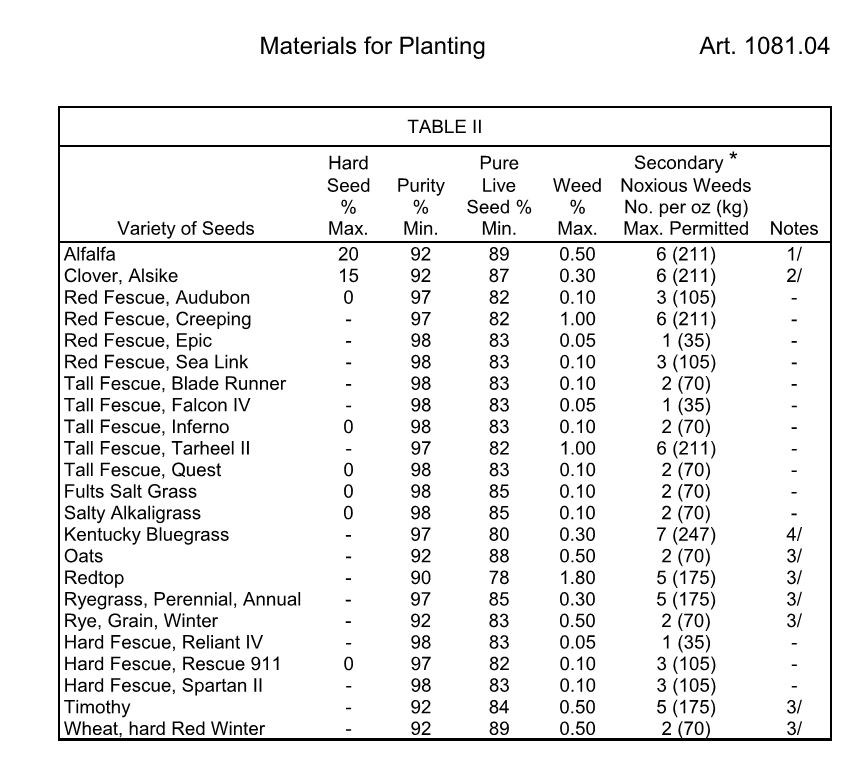

Take a look, again, at the specification excerpts (above) for the Class 4 seed and you’ll notice, next to each of the native grass description, a “5/” reference to the note ” PLS = Pure Live Seed to be used.” This description is self-explanatory – We are only paying for pure live seed delivered to the job.

Well, isn’t grass seed in a bag all just seed?

Not necessarily.

Let’s look at IDOT’s specification that defines what Pure Live Seed is:

You can see, in the analysis of a bag of Kentucky Bluegrass, that we’re buying & applying grass seed, but, we’re also buying & applying some “other stuff.” In the bag analysis, we see “Other Crop Seed” and “Inert Matter” that is included in the bag. Although the seed suppliers processing and packaging seed try to get the product to be as close to pure seed as possible, there are still going to be some leftover, non-seed particles in the bag. And since the bag is sold by weight, and you are applying the seed at an application rate that relies on weight, you have to account for the weight of the “other stuff” so that we don’t pay for it.

So, when IDOT Class 4 seed specifies that Big Blue Stem grass is to be applied at a rate of 5 lbs/acre, we have to calculate how much “other stuff” needs to be factored into the amount of seed we are spreading so that we get 5.0 lbs on the ground.

Essentially, we are going to be applying 5 lbs PLUS a little extra weight to get the 5 lbs we want. Makes sense, right…???

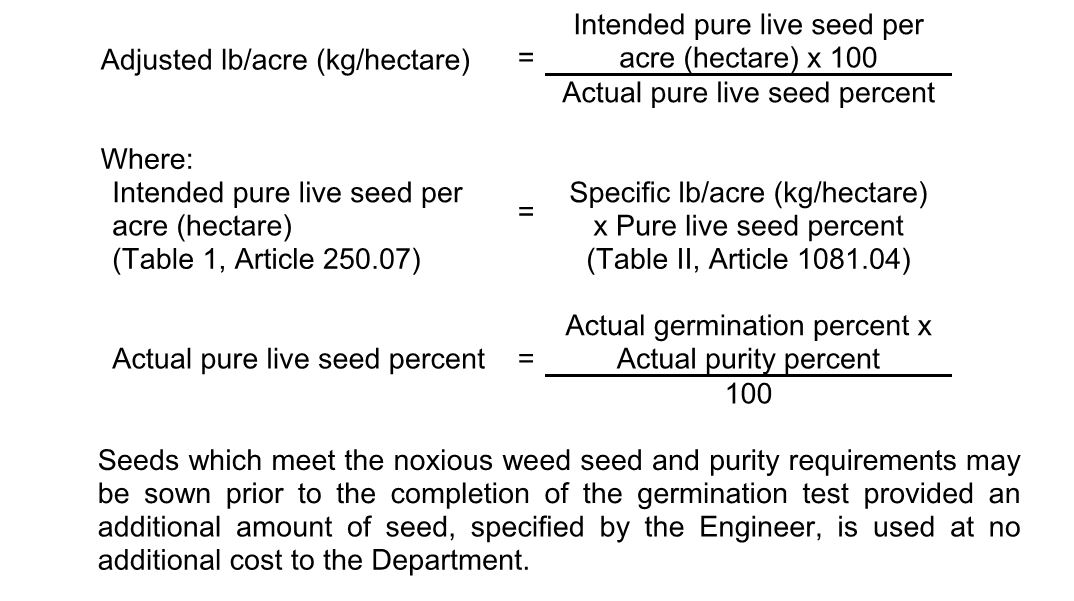

So how do we do that?

Let’s take a look at a couple of seed analyses.

Seed Analysis

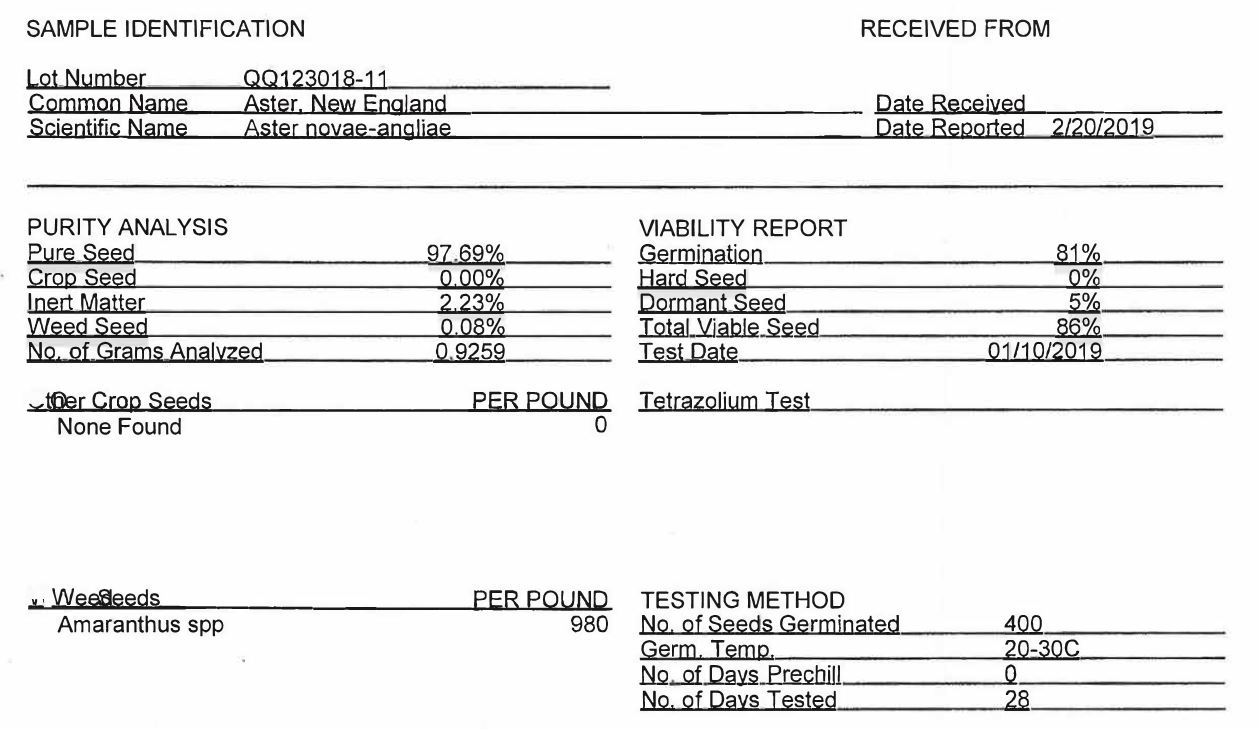

Each seed is sent to a laboratory for testing. The lab will determine the purity of the seed, it’s germination rate, it’s dormancy rate, and other properties that define how the seed will perform. Let’s look at a lab analysis for New England Aster seed.

The lab has determined that 81% of the seed germinated in the lab, 5% remained dormant (meaning that it will germinate when the environmental conditions are correct), and they’ve determined the “other” contents, like weeds or inert matter. And of course, if all the seed didn’t germinate when they ran the test, that percentage is excluded. The lab determined that 86%% of this mix is considered to be growable, Pure Live Seed.

Each grass type in the mix is analyzed in this matter. And from the analysis, we get how much Pure Live Seed we will be receiving and that will include the “other” in the seed blend as well.

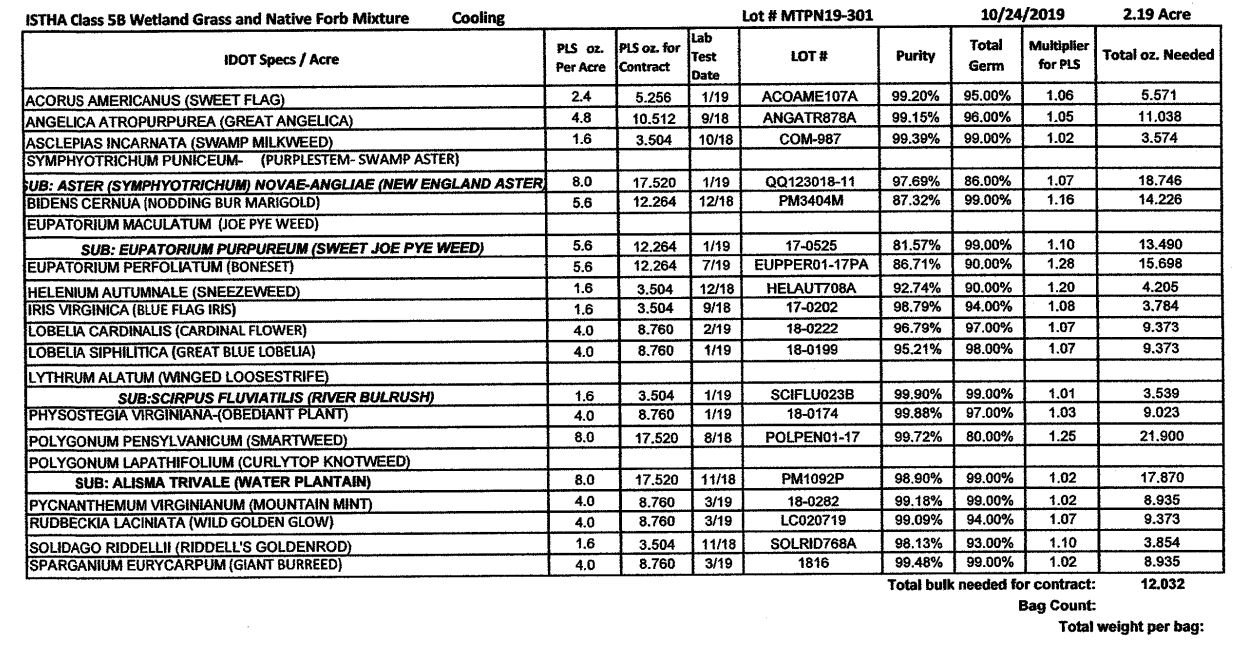

Typically (and I say typically here for a reason), the seed supplier will do the calculation for you and the landscaper that determine seed blend ratios, factor in the “other” and develop the weight of each individual seed type for the particular area needing to be seeded.

So if we take a look at this seed blend ticket, you’ll see how all of these criteria are being factored. You’ll see that the supplier has started his calculation by using the application area the contractor needs to seed. Each of the grass types and specified applications rates are provided. The purity and total germination of each individual seed type are imputed. The worksheet provides the total amount of each seed type needed, with the extra’s and non-germinating seeds factored in.

Doing Your Own Yield Checks

I can’t say this for sure because, well, I’m not a seed supplier, but the vast majority of suppliers who develop seed blends for government agencies, are used to providing all of the certifications that we require. But, in case you seed supplier doesn’t provide you with that backup, the task of checking the yield might fall on you, the Resident. If that’s the case, you’ll need to run through the calculations yourself.

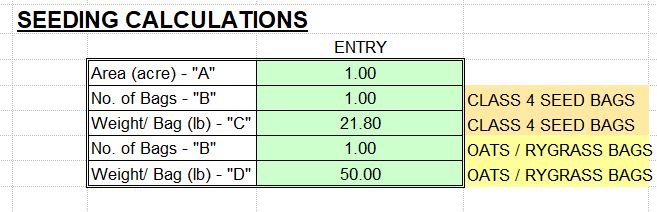

Our crew has used a calculation spreadsheet for years. This is one of those “Legacy Calculation Sheets” that has been changed, tweaked, re-formatted a couple dozen times over it’s lifespan. I made some major changes to the sheet several years ago, but like I’ve said repeatedly on my site, tools can sit in toolboxes and be pulled out anytime you need them, so long as they are sharp and rust-free, you can put them to use – This is one of those tools.

The worksheet is setup by popular seed type that we use in Illinois: We have pre-entered all of the seed blends and application rates. The sheet allows the inspector to enter the area where the seed was applied, the bags of seed provided with their respective weights. These sheets are usually assembled once you have a defined seeded area completed where you can total all of your bags.

The next step is entering all of the seed analyses for the individual seed type. By simply loading the information found on the seed bags & tags we can easily determine if the landscaper adequately seeded our job.

And if You’re Working for IDOT….

IDOT Roadside Development has some specific Seeding Material Inspection Guidelines <<CLICK HERE TO DOWNLOAD THE MEMO>> that need to be followed if you are planting any specialty-type seed classes. IDOT requires that a representative be present when the seed supplier is blending the specialty seed mix. As the Resident, you’ll need to make sure thatthe landscaper, the supplier and IDOT are coordinating this effort.

Also, always be aware of seed planting dates as many of the seed classes have time-of-year restrictions. Anytime your landscaping contractor is nearing the expiration date of the seed classes you have, start the conversation on procedures. Depending on the season and weather conditions, IDOT might grant the landscaper an extra week or two to get the seeds sown. Make sure you document any of the date extensions granted.

After Actions

I’ve said it in previous articles: If you are a construction engineer, you are never an expert. You can, and should, have a strong understanding of all of the facets of your particular project, but you ALWAYS have to be studying your craft. Seed yield checks sound like a really boring topic, and given that we only deal with the issues a couple of times a year, the skills you have can get rusty. Grab some steel wool, keep your tools sharp up and they will work for you when you need them.

Be the first to comment