If you’ve been involved in driving piles, then you certainly know what happens when you are getting into your bearing strata: The piston starts popping out of the cylinder, the lower-muffled “bangs” on the pile start turning into crisp “pings,” and your blow counts per foot start increasing. And as you start to get close to you required blow count & hammer energy delivery, you might start to think about shutting off the hammer – You’re getting to your required bearing.

I’ve written several articles on pile driving: It is one of construction installation operations that get my juices flowing. It’s big equipment run by guys who are great at what they do, I can’t think I’ve every worked with a pile driving crew that I didn’t enjoy working with.

Our company is currently overseeing a project in a railroad yard that will require about 40 piles to be driven. The drive criteria is listed as follows:

All piles shall be driven to an ultimate bearing resistance of 330 tons or refusal…

The pile capacity, at 330 tons (or 660 kips) is a stout pile support system. Fortunately for us, the soil borings show some really stiff clays at around -40 feet BGS (or Below Ground Surface). Bedrock is around -80 BGS. We should have no problems achieving bearing.

Pile Refusal

But, the criteria forced me to do a little research: What driving criteria constitutes “refusal?” Is there a drive criteria for it, or is it just a visual confirmation? At what depth of penetration (say, blows per inch) indicates that refusal has been reached?

You might think that the answer is obvious: Refusal means the pile isn’t dropping anymore, right? Well, it’s true, but, empirically, in terms of blow counts, energy and/or penetration, what determines that refusal has been reached?

For the most part (and I’m being general here for the sake of conversation), observing a pile at the surface, even at very high bearings, the pile will almost always appear to be going down. Even when toeing into bedrock, some sort of apparent depth-gain is occurring. The problem is at very high drive energies and low penetration, we want to make sure that we are not stressing the pile beyond it’s material limitations. The last thing we want to do is deform the pile, which, for piling that may be driven through very weak upper strata, can result (buckling).

So, we don’t want to underdrive a pile, but we do need to achieve our bearing. And, we don’t want to overdrive the pile either. So, when we hit that “sweet spot” of lack of penetration while avoiding pile damage, we’ve reached refusal. The pile has, effectively, ceased penetration. So, how many blows per inch, as an empirical method of determining that refusal was achieved, do we need?

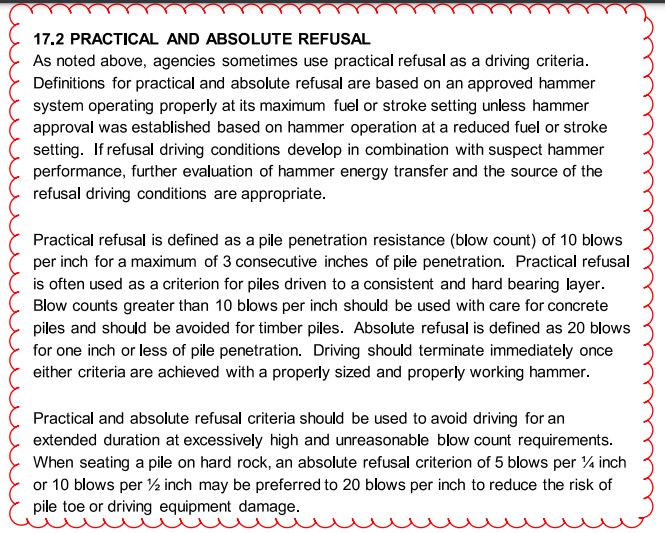

I had to do some research and found, what I believe to be, an excellent criteria. This comes from the FHWA’s “Design and Construction of Driven Pile Foundations (Publication No. FHWA-NHI-16-009).” ” I found these definitions:

I thought it was interesting that there are actually 2 types of refusal. For our railroad project, we’ll be checking with the structural engineer to find out whether we are to achieve “practical” or “absolute” refusal during our driving.

After Actions

It’s not too often that I’ve run across a criteria that cited refusal. Always a day to learn.

Bookmark either this page or the link to the FHWA’s manual. Or better yet, grab your copy of your agency’s specifications book, go into the piling section, and write down the FHWA’s manual number so that you can call it up & refer to it later. It’s not often that refusal is specified as a drive criteria, but, just in case the next pile driving project your on requires you to drive to refusal, you’ll have the ability to quickly-retrieve the criteria and be ready to implement it.

Be the first to comment