I wanted to write a post discussing a design issue that we encountered out here on our site. MicroStation, AutoCADD and the like are the daily tools of choice for almost all designers, and no longer are Kohinor pens, mylar and pin tabs seen except in display cases. With all of the screen time that young engineers are getting, I regularly see design errors that are related to a lack of actual field knowledge. A “Junior Bird Man Error” shows itself at least a few times on every job; designs that look great on the screen but are not actually constructable.

Let’s review a real-time case that has occurred on our project.

SITUATION

Construct a 9′ diameter manhole that serves a 72″ diameter trunk storm sewer AND an adjacent lateral catch basin. Pretty simple, right?

AS DESIGNED

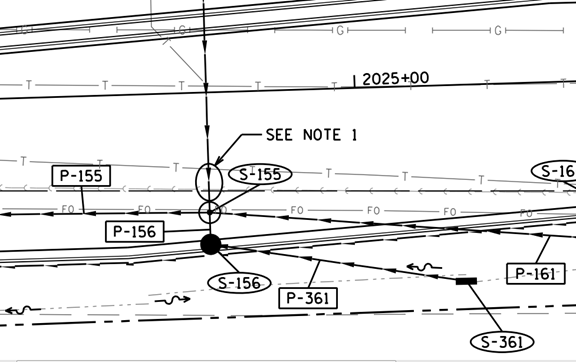

Our designers provided us with the following depiction of a storm sewer installation:

P155 and P161 are 72″ sewers, S-155 is a 9′ diameter structure. S156 is a catch basin that needs to be located to coordinate with the edge-of-pavement.

Looks great in black and white, doesn’t it? Nice and pretty. All the linework is clear, labels are all legible. Everything fits together just perfect….

ACTUAL DESIGN PARAMETERS

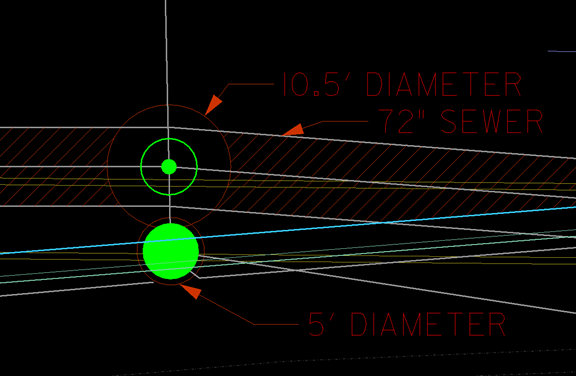

OK, so let’s do a quick review of the physical parameters of the installation. A 9′ inside diameter manhole has walls, right? So does the 4′ inside diameter catch basin, yes? And of course the 72″ pipe has 9″ thick walls, right? All of this “thickness” needs to be accounted for to get all of these elements installed.

So I jumped into Microstation and pulled up what the designer developed, but I went to the next step and gave some “physicality” to the single lines. I added the actual outside lines of the pipe and structures. Hopefully, by now, you can see what’s going wrong….

Yup – We have a mess on our hands. Tab A and Tab B have to both go into Slot C. No bueno. The 9′ manhole and the 4′ catch basin structures overlap.

The picture below is of a 9′ diameter manhole at a different location. I wanted to give some perspective as to the size of the structure – note how the size of this bad boy dwarfs the 3 grown men working on it. We’re dealing with Big Kid Structures and Big Kid Pipe here.

PROGNOSIS BY A DESIGNER

OK, so if you’re a designer, you’re probably saying, “Hey, that’s OK, that’s why we have field guys, that’s what they get paid to do, solve problems in the field. You guys can just make a field adjustment, move things around a little bit, and it will work fine.”

Right? It’s so easy.

Listen to me: Don’t let the words come near your fingertips – That’s a cop-out. Don’t be an excuse-maker. This design is jacked-up. And now it’s got to be fixed. You came to this blog to hear about tough love. Here’s the truth. This is going to cost some money to get it fixed.

PROGNOSIS BY A CONSTRUCTION ENGINEER

The reality of this situation was a mess. The 72″ pipe was being installed. You just can’t “rotate” the lateral’s entrance into the manhole since you’d have no manhole wall left to support the lid. With smaller pipe, yes, you can “crack” the pipe joints a bit to swing a pipe slightly off-line, but with Big Boy pipe, nope, can’t do it.

HARD TRUTH

Encountering errors like this frosts my pumpkin. Why? Because they shouldn’t occur. Period. This isn’t a bad design, this is bad quality control. This is an error that made its way through the design process, a process that should have quality checks along the way. This is an error that a senior-level engineer, reviewing the plans, should have been able to catch. It’s sloppy.

Look, I’ve been in the design trenches. It’s easy to lose sight of the details when you are digging as fast as you can. Drainage design requires constant adjustments during the design process, between pipe sizes, structure locations, slope adjustments, all of which funnel back to the capacity calculations that need to be re-run and re-checked constantly. I get it. I’m not envious. I did it for a church parking facility. It was fun once. I got my ticket punched, it’s now off my Civil Engineering Bucket List. Sign the next guy up, I’ve already lived it.

Good companies make it a point to have their construction guys review the design guys’ plans. Bad companies don’t. Good young engineers ask questions of their senior engineers to review their work. Young engineers plow through design work without taking into consideration the 3-dimensional aspect of what they are designing. No bueno….

ADVICES (sic Arnold Schwarzenegger)

Young engineers can do a few things to avoid situations like the one I’ve depicted.

1. Think In 3 Dimensions

I learned, very early in my career, how to look at a problem. I was fortunate that my first real-world job was being a construction inspector on a residential water main replacement project. I didn’t know a thing about design, but I got to see how things got into the ground. I learned to appreciate the physical nature of building something using manpower and big equipment. When I got into design, I always felt that I had an “edge” since I had a propensity to always think about how something I was working on would get built.

I wish that more companies allowed the young engineers the opportunity to work in the field. If you can find a company that offers some type of “rotational experience,” I highly recommend you consider working for them as it will make you a very well-rounded designer.

Step back from what you are designing and think of construction. Consider the physical properties of what you are working with. Think XYZ: What do the design elements I’m dealing with actually look like? Can the guys in the field build what I am drawing? Will it fit together? Am I providing spatial tolerance? Have I considered all of the physical elements around what I’m designing, like utilities or live lanes of traffic?

2. Ask Questions

It’s really easy to think we know the answers to everything. Let’s face it: We’re engineers, we get paid to solve problems, we’re really smart. Why should I lower my standards and ask for someone to review my work? I’ve got this, don’t you worry….

Here’s a tip: When you come to work, leave your ego at the door.

As much as I’d like to think I’m the smartest guy in the room, it’s NEVER the case. Sure, I’ve built a lot of shyt in my years. But everyday that I go to work, I’m asking questions. A lot of times, I know the answer, not because I’m smart, but because I’ve encountered a similar situation before and can apply it to the current problem. Or because I’ve taken the time to sit down with a cup of coffee, stare at the problem, and have tried to solve it on my own. Really, I don’t have to be The Know-It-All in the room. In fact, I am much more comfortable being the guy in the engine room, cranking out power for the captains to use to keep the ship heading in the right direction.

Be the kind of engineer who knows how to ask for assistance. Don’t be afraid to ask questions, even when they might be stupid ones. Be the kind of engineer who enjoys being the Devil’s Advocate. Question everything about your design. Let others critique what you are working on. Step back from your design and look at it from 90-degrees. Does it look the same? Will it still accomplish the design parameters? How can I tweak it to make it 1% or 2% better?

Everyday is a day to learn. Today, after reading this, is that day for YOU. Step away from the Microstation monitor for a second. Run a check plot of what you’ve drawn. Now stare at it. Build it in your mind. Be the Contractor and figure out how you are going to get all of those lines built. Better yet, be the Contractor who wants to take advantage of your design to make some extra money at your company’s expense by finding something that you missed. Now pick up the print. Does it look the same, or do you see opportunities for improvement. Walk over to another work station, and ask somebody to look at it. See what they say.

Repeat this process over and over and over. Become better. Improve. Learn.

Be the first to comment